SCADA Maintenance Contract / Lift Station PLC Upgrade 2017 (27 Sites) City of Naperville, Naperville, IL

Scope of Work

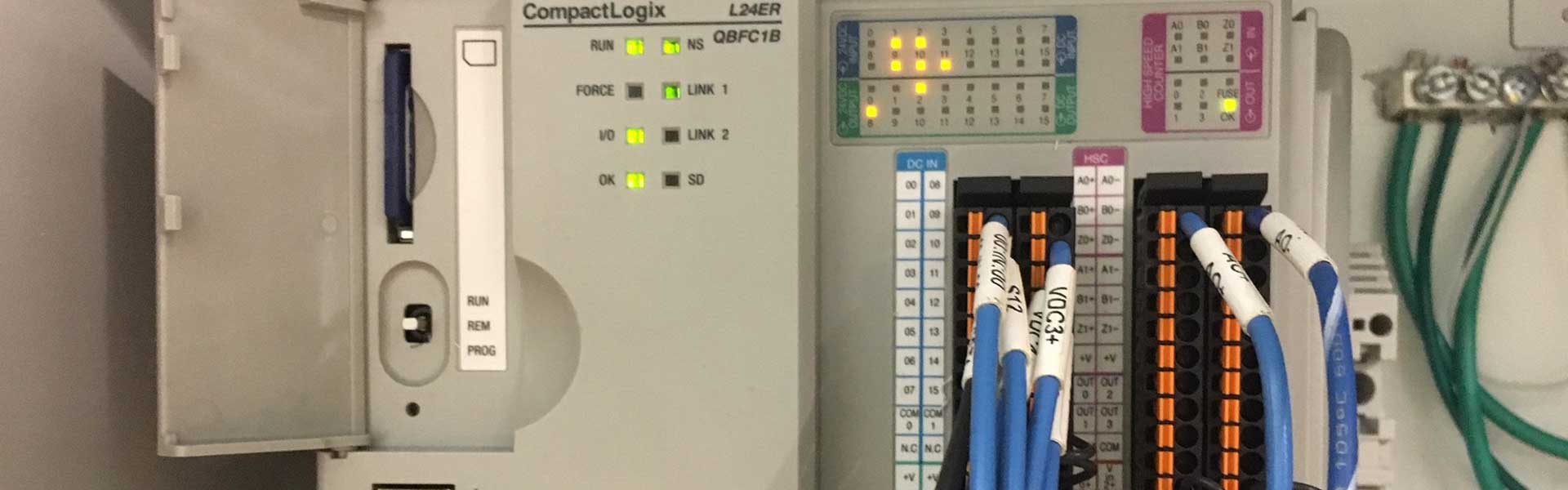

Maintain the Cities Water/Wastewater SCADA and Control Systems. Primary services provided are SCADA HMI Software development, database management, water and waste water control system instrumentation and PLC programming / troubleshooting. AAC integrated a new SCADA network which consists of two full-function Intellution iFix SCADA nodes with “Hot” standby redundancy, one client node and one terminal server. Each SCADA node is networked to both the water and wastewater systems. The physical system consists of 26 lift stations, 2 master locations and a wastewater treatment facility. The PLC architecture utilizes Allen-Bradley based controllers for there control platform. AAC provides the programming services for these facilities covering both maintenance and process upgrades. Other services provided under this contract include calibration, design and commissioning of various control system. Upgraded all lift station locations within the Naperville’s system from Allen-Bradley SLC-5/05 platforms to Allen Bradley CompactLogix platforms. All software conversion from SLC to CompactLogix platforms was integrated. Each site was also integrated using a Beijer 10” OIT. The network platform that we have integrated with all of the cities system is a 900MZ/Ethernet wireless network. The network covers all water and sewer processes with the City. Once the SCADA information comes into various master PC’s, it is then networked into the Cities infrastructure utilizing CITRIX. All data, reporting, alarming and trending are available at all Naperville SCADA PC locations.Lift Station SCADA System / Plant Upgrade 2017 / Maintenance Support City of McHenry, McHenry, IL.

Scope of Work

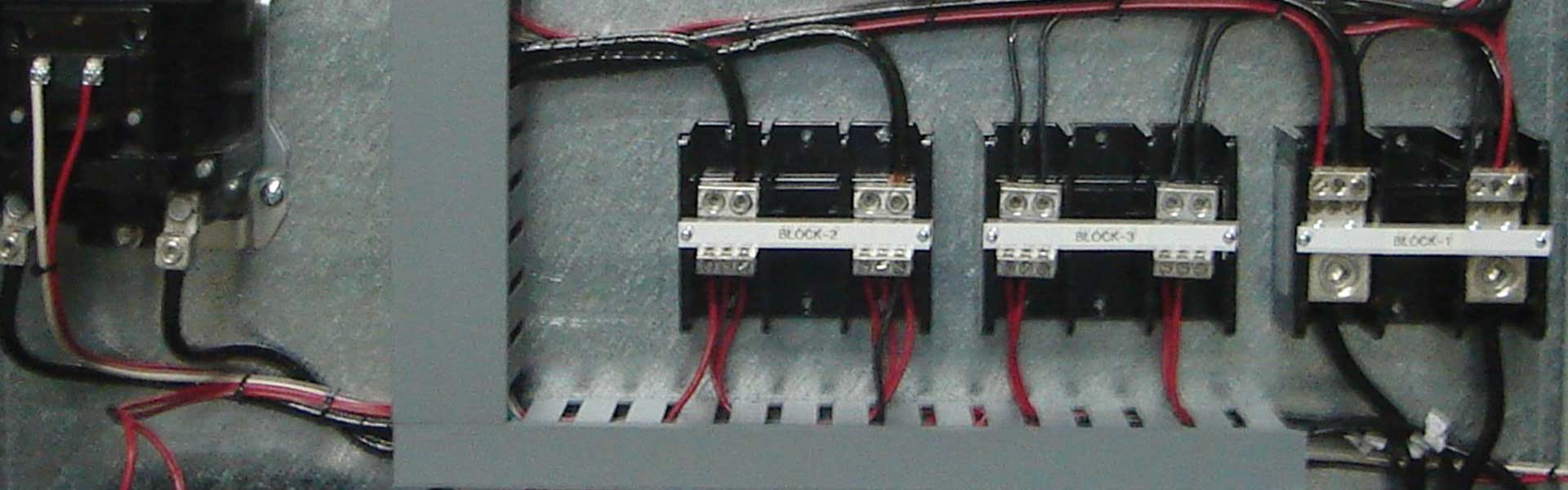

Provide maintenance and upgrade services to the Villages SCADA and control systems. This involvement covers all aspects of the client’s system from process control programming to electrical design and engineering functions. In 2012, AAC integrated and upgraded all the Cities lift station utilizing GE VersaMax PLC’s for monitoring and controls. Where required, the existing panels were removed and new panel put in place. The communications architecture is a 900 mHz unlicensed radio system. All station data is communicated back to the Cities WWTP’s SCADA computer. Data, Alarming, setpoint control and trending are all integrated into the system. Other services provided under this contract include calibration, design and commissioning of various control system. Current WWTP Upgrade is under construction. AAC is responsible for all SCADA and Controls integration to the $33M project. Integration includes over all plant communications and controls between station and vendor control panels. All communications within the plant is TCP/IP Ethernet over fiber-optic cabling ring network. All processes in the plant are monitored and controlled utilizing AB PLC platforms. AAC is providing all field devices such as flow meters, transmitters, VFD’s, switches, control panels, Etc. Installation, start-up and training are the responsibility of AAC.Water and WasteWater / Capital Project Services /Maintenance upport Contract Village of Carpentersville, IL

Scope of Work

Advanced Automation and Controls contracted to provide all SCADA and process control services as required for the Village. Both the Water and Wastewater departments are supported for all their process control needs. Both systems run on AB PLC platforms as well as GE iFix SCADA software. Service provided include design build, calibrations, programming, field troubleshooting and startups.SCADA System Upgrade / Maintenance Support Contract Village of Palatine, Palatine, IL

Scope of Work

Advanced Automation and Controls is providing a “turn-key” solution for the Village for the purpose of upgrading their existing SCADA system. The project has been designed in two phases. Phase I involves the design and specifications for the system and Phase II involves the integration of the SCADA system. Advanced Automation and Controls is responsible for the entire process. The basic architecture that will be utilized is an Allen-Bradley PLC based control system communicating via a wireless network. All system data is communicated back to the public works facility and is monitored by redundant Intellution iFix SCADA nodes. A local SCADA network will be developed with four additional client nodes. The Village is capable of monitoring and controlling various set points and alarms throughout the system from their public works facility. All PLC programming and integration as well as control panel design and fabrication will be is provided by AAC. All water and WW facilities are integrated with Allen Bradley SLC 5.05 PLC’s with a communications architecture utilizing 900mHz/ethernet wireless communications. All the sites communicate directly back to the public works facility for monitoring and controls. A total of ten (10) sanitary lift station and forteen (14) water system sites communicate back to the PW facility.SCADA System Upgrade Water System Village of Fox Lake, Fox Lake, IL

Scope of Work

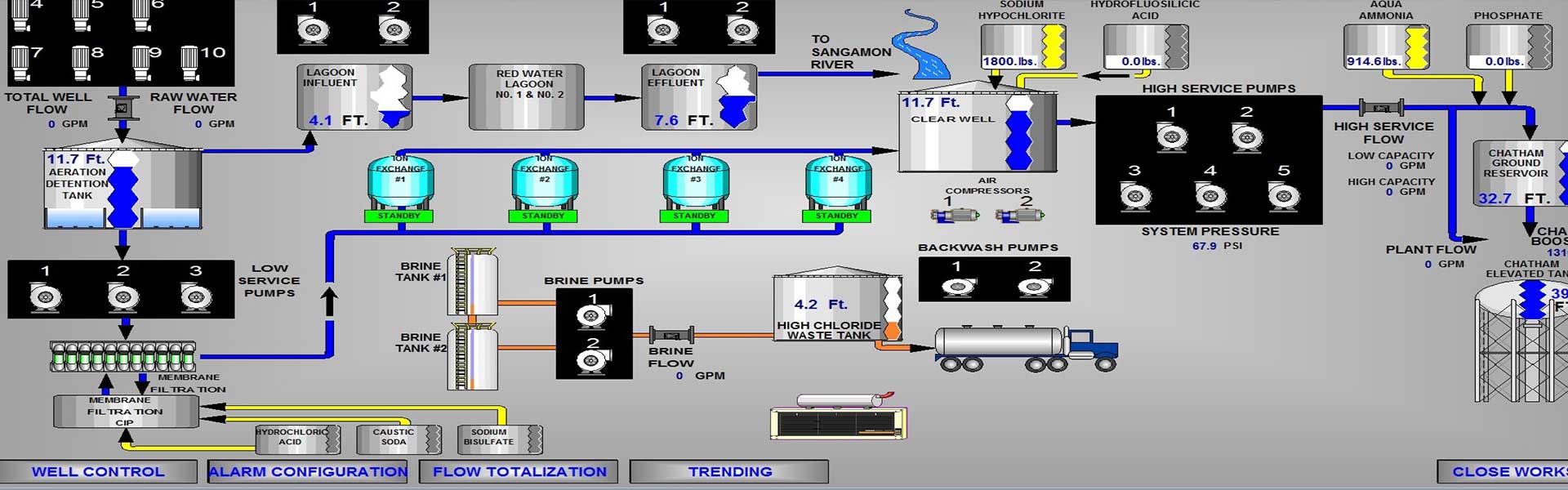

Advanced Automation and Controls was contracted to provide a new SCADA system upgrade to the Village;s water system. The system includes two water towers, one above ground reservoir, and five well locations. The system was designed to communicate via 900Mhz spread spectrum radio. All data is transmitted back to the Fox Lake Main Plant. System architecture consists of Allen-Bradley MicroLogix and CompactLogix PLC’s. Each location is designed with distributed control philosophy in place. The master SCADA consists of 3 InTouch Wonderware SCADA nodes as well as remote access to the system via Wi-Fi connectivity. All alarming and alarming distribution is provided via Win-911 alarming software, which allows the Village to select which alarms are available and what action does the alarm provide. A standardized report was created using XLReporter. XLReporter is an Excel based reporting software that integrate into the systems database so that the user can define what data is populated with a report. AAC set up the initial plant and operation report structures for the Village.SCADA System / I&C Upgrade – WWTP / Maintenance Support Contract Village of Rantoul, Rantoul, IL

Scope of Work

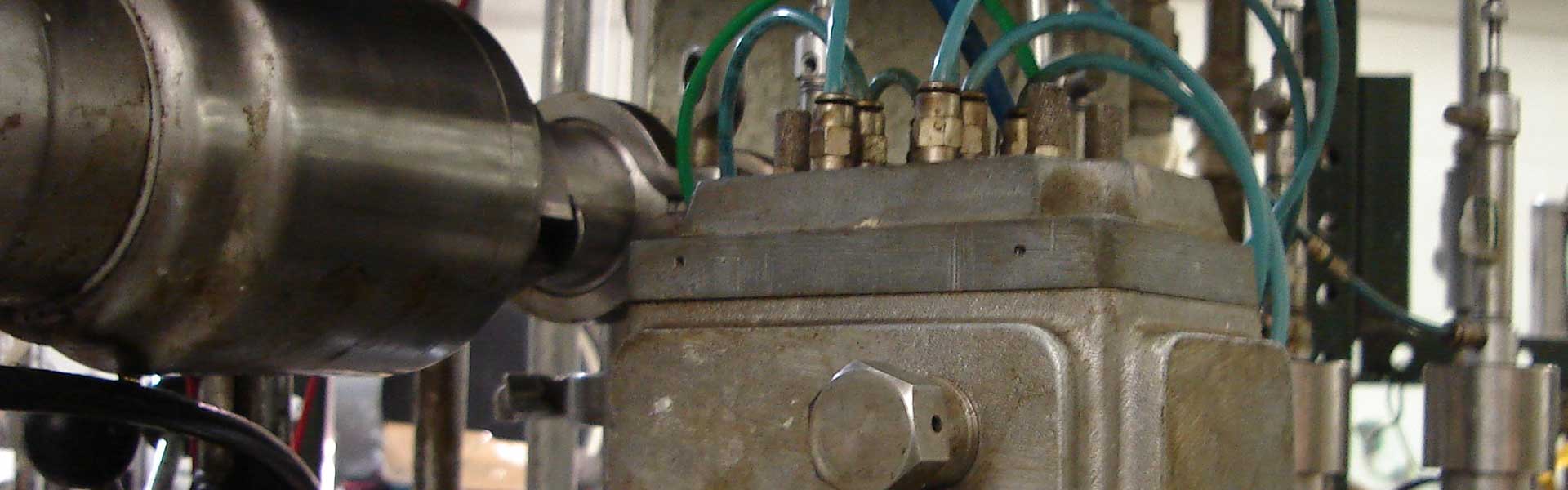

Advanced Automation and Controls contracted to provide the I&C portion of the WWTP upgrade. All required instrumentation and controls were provided and integrated into to new plant expansion. PLC architecture consists of Allen-Bradley PLC’s , OMNI RTU’s and Intellution iFix Redundant SCADA node. Plant operations as well as custom reports, alarming and trending have been implemented into the new architecture. The plant was setup utilizing fiber optic communications and the remote lift station are set up to communicate on a 2.4 and 900 MHz wireless network. All interfacing between plant PLC and vendor driven PLC panels was integrated via Modbus TCP/IP or Ethernet communications.Municipal Clients (Partial List)

City of Naperville, IL

Village of Palatine, IL

City of Evanston, IL

Village of Carpentersville, IL

City of McHenry, IL

City of Darien, IL

City of Byron, IL

City of Marengo, IL

Village of Johnsburg, IL

Village of Richmond, IL

Town of Cortland, IL

City of Harvard, IL

Village of Chatham, IL

Village of Rantoul, IL

Village of Gilberts, IL

Village of Capron, IL

Village of Pingree Grove, IL

Village of Grayslake, IL

City of Crystal Lake, IL

City of Oregon, IL

Village of Oak Park, IL

Village of Antioch, IL

Village of Sugar Grove, IL

Village of New Berlin, IL

Village of Channahon, IL

Village of Kirkland, IL

City of West Chicago, IL

Wasco Sanitary District

South Sangamon Water Commission

Curran Gardner Water Commission

Utility and Manufacturing Clients (Partial List)

Southern Gas (Nicor Gas)

Waste Management

Metals USA

RAE Corporation

Battery Builders Inc.

Fresh Express Foods

Quest Manufacturing

Water Remediation Technologies (WRT)

RKA Integrated Systems